Smart Manufacturing Platforms

Tech-enabled factories increase productivity, efficiency, and visibility. We help manufacturers digitize operations and scale intelligently.

Enable real-time data from machines, track productivity, and automate alerts using IoT sensors and dashboards.

Integrate systems for production, inventory, order tracking, and vendor management with custom dashboards.

Use AI to forecast demand, optimize supply chain, and detect anomalies in production using real-time analytics.

Why Choose Cherry Tech

• Experts in manufacturing tech, ERP, IoT & plant management systems

• Real-time machine data integration and dashboards

• Automation-first design thinking to reduce downtime

• Predictive analytics and visual monitoring tools

• Experience in MES, vendor portals, production tracking, and audit workflows

• Secure infrastructure, scalable solutions, and support for large deployments

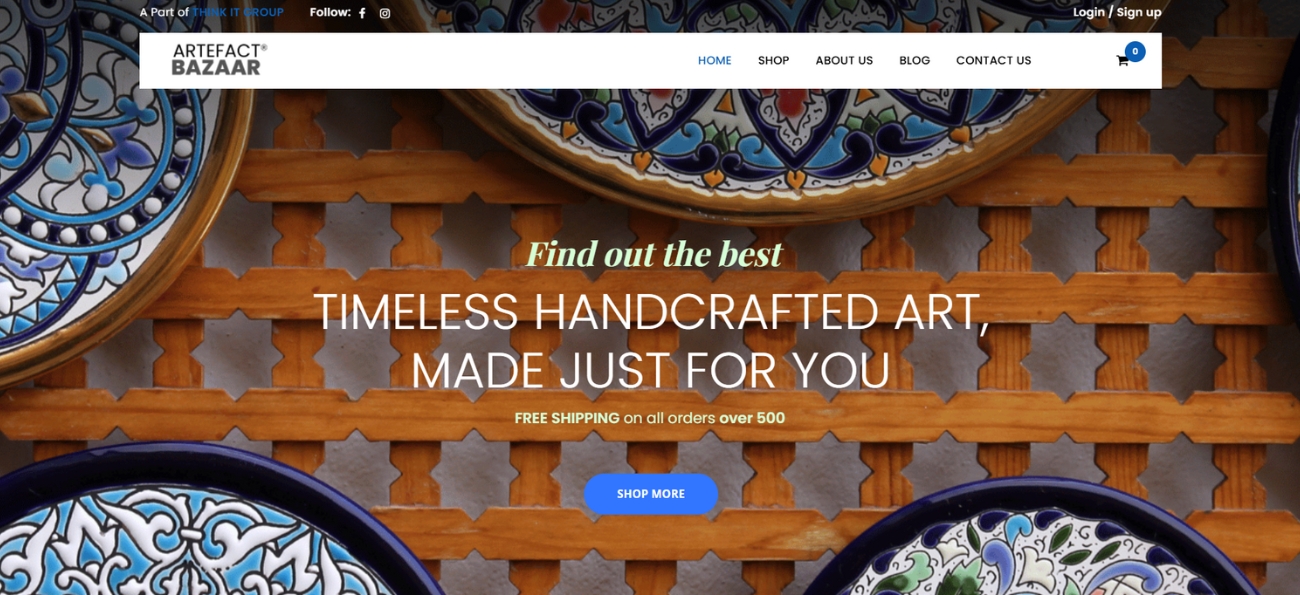

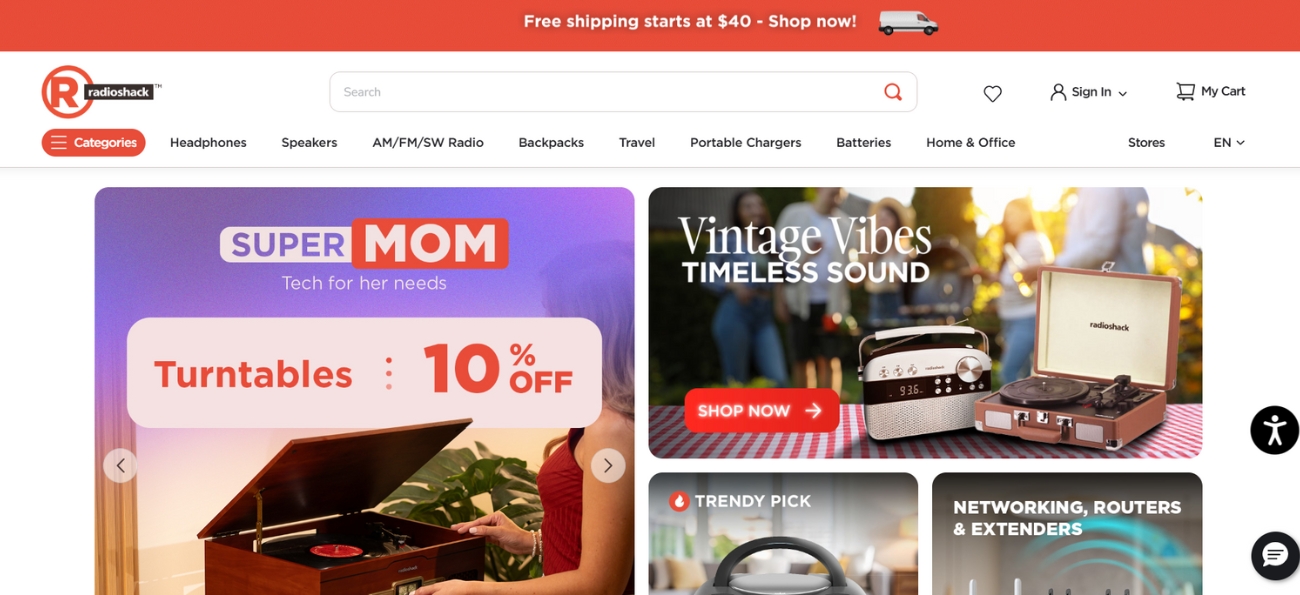

Recent Projects

Our Manufacturing Tech Process

We digitize factories, connect data points, and empower decisions via automation, analytics, and real-time dashboards.

Industry Needs Mapping

Analyze plant workflow, challenges, and IoT potential.

UX Planning & Integration Mapping

Plan dashboards, machine data views, integrations.

IoT & ERP Integration

Connect factory machines, software, and analytics dashboards.

QA, Alerts, Security Testing

Test IoT triggers, downtime alerts, security issues.

Training & Pilot Rollout

Train operators, deploy pilot, scale gradually.

Analytics, Reporting & Scaling

Use dashboards to forecast, monitor and grow.

Frequently asked questions

Can you integrate factory machines with software?

Yes — we’ve built platforms that connect IoT sensors, PLCs, and SCADA systems to software dashboards. We use MQTT, Modbus, and custom APIs to stream real-time production data to admin panels and mobile apps. Alerts can be configured for deviations, faults, or production delays.

Can we digitize old ERP and Excel systems?

Absolutely. We migrate existing Excel/ERP-based processes into cloud dashboards with user roles, live reporting, and automation. You’ll gain better accuracy, access, and integration capabilities without losing old data.

Do you build predictive analytics for supply chain?

Yes — we implement AI/ML-based forecasting for demand, maintenance, and resource planning. We connect warehouse stock levels with production timelines and order projections for smarter scheduling.